rapid injection mold tooling USA

At LXG Mould Tooling, we bring your product ideas to life with precision and speed. As part of LongXiang-Ltd, we specialize in world-class injection molding services and advanced injection mold tooling solutions trusted by innovators across the globe. With two decades of expertise, cutting-edge equipment, and a dedicated team of engineers, we transform your designs into reliable, scalable plastic parts — on time and on budget.

Get In Touch With Us

Welcome to LX Mold Tooling

Your journey from concept to product deserves a partner who can deliver more than just parts. That’s where we come in. At LXG, we provide a complete package — from rapid tooling injection molding for quick prototypes to long-lasting injection molding tools for mass production.

We don’t just mold plastic. We mold trust, quality, and long-term partnerships.

Why Many Companies Struggle

We’ve seen it too often — businesses stuck with partners who:

Deliver injection molding tools that wear out quickly

Take months for mold fabrication

Limit design possibilities due to poor engineering support

Inflate costs with inefficient manufacturing

Fail to meet global compliance and certification standards

Why Choose Us?

Partnering with LXG means choosing more than a supplier — it means gaining a strategic manufacturing partner committed to your success.

Deep Expertise & Legacy

As part of LongXiang-Ltd, LXG inherits decades of mold-making and production know-how.

Full Turnkey Solutions

From concept and mold design to prototyping, production, and finishing, we provide end-to-end execution under one roof.

Wide Material Range

We support commodity plastics, engineering resins, elastomers, high-performance polymers, and eco-friendly materials.

Scalable Capacity

Whether you need pilot runs of 100 parts or millions of production units, we scale seamlessly.

We Are Best Ever

3000+

Molds Delivered Worldwide

200+

Project Completed

38+

Countries Served

1,200+

Professional

Mold Tooling Service We offer

Prototype & Bridge Molding

Need to validate your design quickly? With rapid tooling for injection molding, we create test parts in just a few days for design validation, fit checks, and early user feedback.

Production Injection Molding

Our hardened injection molding tools deliver consistent quality and long tool life for millions of parts — without compromising on speed.

Overmolding & Multi-Material Solutions

Using 2K/3K technology, we mold multiple plastics in one component. Ideal for ergonomic grips, protective casings, and functional integration.

Insert Molding & In-Mold Assembly

Metal inserts, sensors, or threaded fasteners — we embed them directly into your part during molding, eliminating secondary steps and reducing costs.

Global Tooling Manufacturing

We’ve built over 3,000+ injection mold tooling projects for clients in aerospace, automotive, medical, robotics, and consumer industries. From Detroit to Munich to Shanghai, we combine global delivery capacity with responsive local support.

Our Proven Process — From Idea to Market

Step 1. Consultation & Instant Quote

Your journey starts with a conversation. We review your CAD files, drawings, or concepts and discuss your goals, budget, and timelines. Using our expertise in injection mold tooling, we provide an accurate quote and initial project roadmap.

👉 This ensures you know exactly what to expect before investing in tooling.

Step 2. Design Review & DFM

Our engineers carefully analyze your design. We check draft angles, wall thickness, part geometry, and resin compatibility. By applying rapid tooling for injection molding principles, we identify possible risks early.

👉 This step prevents costly redesigns and accelerates your time-to-market.

Step 3. Rapid Prototyping with Soft Tooling

Before committing to full-scale production, we create prototypes using rapid injection mold tooling techniques. These soft aluminum or hybrid tools simulate production conditions, letting you:

Validate fit and function

Test assembly with other components

Gather user feedback

👉 With rapid tooling injection molding, prototypes are delivered in days, not months.

Step 4. Mold Manufacturing

Once the prototype is approved, we build your production-ready injection molding tools. These are usually made from hardened steel for long-term durability. Every tool is precision-machined, polished, and tested to ensure dimensional accuracy.

👉 Strong injection mold tooling ensures consistent part quality for millions of cycles.

Step 5. Trial Runs & Validation

We don’t rush into full production. Instead, we run short batches to verify performance. Using CMM inspection, FAI (First Article Inspection), and SPC (Statistical Process Control), we check:

Part accuracy

Resin behavior

Tool performance

👉 This validation phase confirms your parts meet all functional and cosmetic requirements.

Step 6. Full-Scale Mass Production

With validated injection molding tools, we move into full production. Whether you need 100 parts or a million, we ensure repeatability and efficiency.

👉 This stage highlights the advantage of injection mold tooling — high yields, low per-part cost, and consistency at scale.

Step 7. Secondary Finishing & Assembly

Your product doesn’t stop at molding. We offer:

Painting, polishing, or texture finishing

Pad printing and laser engraving

Insert installation or overmolding

In-mold assembly with electronics or fasteners

👉 Combining rapid tooling injection molding with finishing under one roof saves time and cost.

Step 8. Packaging & Delivery

Finally, we package your parts securely and arrange global shipping. With over 3,000 molds delivered across 38 countries, LXG ensures safe, on-time delivery every time.

👉 Our global footprint means your injection molding tools and finished parts reach you wherever you are.

At LXG Mould Tooling, we believe that clarity and discipline at every stage make the difference between a failed product and a market success. That’s why our process is designed to give you confidence — from the very first conversation to the delivery of finished parts.

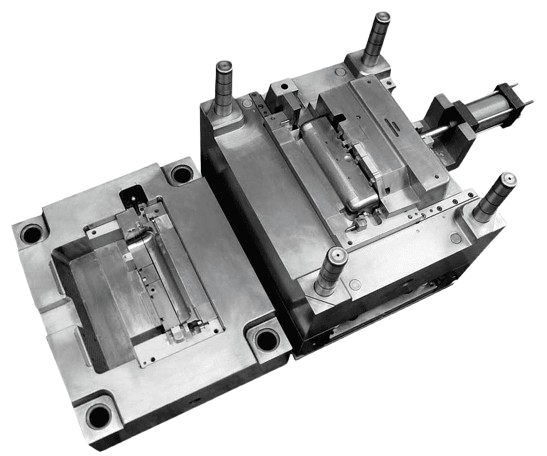

Rapid Mold Tooling Workshop

Differentiators That Make LXG Mold Tooling Better

| Feature / Benefit |

| Process Support |

| Material Range |

| Scalability |

| Lead Times |

| Order Size |

| Quality Assurance |

| Services |

| Global Reach |

| Confidentiality |

| Sustainability |

| Typical Competitors |

| Limited engineering support |

| Limited to common resins |

| Either prototype-only OR mass production |

| 6–12 weeks typical |

| Often high MOQs |

| Standard inspections only |

| Molding only |

| Limited regional service |

| Basic NDAs |

| Not always prioritized |

| LXG Injection Tooling |

| Full DFM/DFA reviews & proactive feedback |

| 100+ materials including high-performance & medical grades |

| Seamless scale from 1 part to millions |

| Prototypes in 5–7 days, production in 3–5 weeks |

| No minimum order quantity |

| ISO-grade SPC, FAI, CMM, traceability |

| Tooling, molding, finishing, assembly under one roof |

| Delivered 3,000+ molds to 38+ countries |

| Strict IP protocols, secured data handling |

| Recyclable resins, eco-friendly processes, energy-efficient machines |

Our Testimonials

our client say's

At LXG Mould Tooling, we specialize in delivering high-quality, cost-effective, and scalable plastic manufacturing solutions. As part of LongXiang-Ltd, we bring more than two decades of global expertise in injection mold tooling and advanced production systems. From startups launching new products to Fortune 500 companies optimizing global supply chains, we provide a trusted pathway from idea to finished part.

Industries We Serve

At LXG Mould Tooling, we understand that every industry has unique requirements when it comes to performance, compliance, and scalability. That’s why we don’t just provide injection mold tooling — we tailor our process to meet the exact needs of your sector. From fast prototypes using rapid tooling for injection molding to long-term production with hardened injection molding tools, we deliver solutions trusted worldwide.

- Aerospace

In aerospace, every gram matters — and so does every micron of precision. Our injection mold tooling supports the creation of lightweight yet durable parts used in aircraft interiors, unmanned systems, and even launch vehicle components.

Rapid injection mold tooling enables wind tunnel prototypes and test models in record time.

Hardened injection molding tools guarantee long production runs for high-performance plastics.

Compliance with aerospace standards ensures your parts are flight-ready.

👉 From fit-and-function prototypes to hot-fire tested components, LXG helps aerospace companies reduce weight, boost performance, and shorten development cycles.

- Automotive

The automotive sector demands speed, scale, and cost-efficiency. We support traditional, electric, and autonomous vehicle manufacturers with injection mold tooling designed for high-volume, repeatable production.

Dashboards, trims, housings, and interior panels produced with precision injection molding tools.

Rapid tooling injection molding for fast prototype builds during vehicle development.

Strong tooling for millions of cycles, ensuring part consistency across large fleets.

👉 Whether it’s a concept EV connector or a production dashboard assembly, our rapid tooling for injection molding keeps you ahead in a fast-moving industry.

- Consumer Electronics

Modern electronics need compact, reliable, and aesthetically pleasing enclosures. Our injection mold tooling solutions deliver sleek casings, functional housings, and protective connectors for devices people use daily.

Rapid injection mold tooling produces quick-turn prototypes for new device launches.

Multi-material and overmolding technology adds grip, comfort, and style.

Injection molding tools guarantee tight tolerances for miniature components.

👉 With our expertise, your next gadget is not just functional — it’s production-ready, stylish, and durable.

- Medical & Healthcare

Patient safety and compliance are non-negotiable. That’s why our injection mold tooling for the medical sector is built with ISO 13485-certified processes and FDA-approved resins.

Rapid tooling for injection molding supports early prototypes for life-saving devices.

Biocompatible resins and cleanroom assembly ensure medical-grade quality.

Precision injection molding tools maintain strict tolerances for surgical and diagnostic equipment.

👉 From disposable syringes to advanced surgical housings, LXG ensures every part is safe, reliable, and compliant.

- Industrial & Robotics

Robotics and industrial systems need rugged, high-performance parts that can handle stress, vibration, and wear. Our injection mold tooling delivers components designed for endurance.

Fiber-reinforced polymers molded using hardened injection molding tools.

Rapid injection mold tooling for quick prototypes in automation development.

Large, complex housings and gears built for heavy-duty operations.

👉 Whether you’re building automation systems or next-gen robots, our rapid tooling injection molding solutions keep your machines running longer and smarter.

- Sustainable Packaging

The future of packaging is green — and we’re part of the solution. LXG partners with eco-conscious brands to develop biodegradable, recyclable, and lightweight packaging using injection mold tooling that balances sustainability with performance.

Rapid tooling for injection molding prototypes allow fast testing of eco-friendly designs.

Thin-wall injection molding tools create lightweight, material-efficient products.

Support for biodegradable and recycled resins.

👉 From compostable containers to reusable packaging, our rapid injection mold tooling helps brands reduce carbon footprint without sacrificing quality.

Get In Touch With Us

Frequently Asked Questions (FAQ)

Choosing the right injection molding partner often comes with many questions. At LXG Injection Molding, we want to give you clear, detailed answers so you feel confident every step of the way. Below you’ll find our 15 most frequently asked questions with in-depth responses.

How fast can I get my first molded parts?

With rapid tooling for injection molding, prototypes can be ready in as little as 3–7 days depending on design complexity and material availability. For production runs, once your injection mold tooling is approved, lead times are typically 3–5 weeks. Our goal is always to cut weeks off traditional timelines with rapid injection mold tooling techniques.

Q2. Who owns the mold after production?

You do. At LXG Mould Tooling, all injection mold tooling we design and manufacture belongs to you, the client. Unlike many suppliers, we don’t hold ownership over your injection molding tools. This gives you complete control and flexibility to transfer molds if needed in the future.

Q3. Do you require a minimum order quantity (MOQ)?

No. We understand different projects have different needs. Thanks to our scalable injection molding tools, we can produce as few as one prototype or scale up to millions of units. Our rapid tooling injection molding capabilities make it possible to support both startups and global manufacturers.

Q4. How do you ensure part quality and consistency?

Quality is our priority. Every part goes through strict checks — including FAI (First Article Inspection), CMM (Coordinate Measuring Machine) reports, and SPC (Statistical Process Control). Our precision-built injection mold tooling guarantees repeatability, while our global standards ensure compliance across industries such as medical, aerospace, and automotive.

Q5. What makes LXG different from other injection molding suppliers?

Many suppliers only provide molding. LXG offers a full turnkey solution — from DFM reviews and rapid tooling for injection molding prototypes to production, finishing, and assembly. We specialize in rapid injection mold tooling for fast launches, support a wide material range, and deliver molds to 38+ countries. With us, you’re not just buying injection molding tools, you’re gaining a long-term manufacturing partner.